Roll Former

Roll Former

Good Quality of Steel & Metal Working Technology

by Elaborate Machine Group Design Know-how

TradeBelt Consortium has been designing, supplying and maintaining the Heavy/medium/light weight steel structure forming facilities for several decades for the Korean and Foreign Markets.

We would like to suggest, design and manufacture by Buyers’ customized inquiries and performance while doing our best to meet their initial budget layout.

We would like to suggest, design and manufacture by Buyers’ customized inquiries and performance while doing our best to meet their initial budget layout.

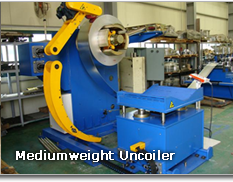

Uncoiling Section

- Loading Capacity : 3, 5, 7.5, 10, 12, 15ton

- Coil Width : max. 500mm

- Type : Center Level Hydraulic-Expanded Mandrel

- Drum Open/Close Distance : Ø470mm ~ Ø520mm

- Drum Drive : AC Geared Motor 2.2Kw with Chain Gear (Inverter Control)

- Main Body : Welded Steel Structure

- Main Shaft & Gear : Hard Steel with Heat Treatment

- Grease : Manual Grease Gun

- Coil Guide : Manual Setting Type

Pinch & Rough Leveler

- Pinch Roll : Ø100mm×500mm×2 PCS, Plated with MC Nylon, Roll Opening 30mm

- Leveler : 3 Sets of Roller

- Up/Down of Upper Roll : Pneumatic Cylinder

- Work Roll : Ø90mm×500mm×3 PCS, Hard Steel with Grounding & Heat Treatment

- Feeding Speed : 10m/min

- Drive : AC Geared Motor, 1.7Kw

- Main Body : Welded Steel Structure

Guide Roller

Rail Roll Forming Line

Roll Forming Machine & Forming Roller

- Guide Roller

- Roller Material : SKD 11

- Roller Quantity : 2PCS

- Roller Diameter : Ø80mm

- Width Adjustment : Manual Handle Type

- Frame : Welded Steel Structure

- Main Frame

- Type : Cassette Fixed Type

- Quantity of Stage : Depending on Steel Structure Shape

- Frame : H-Beam & Welded Steel Structure

Roll Former & Forming Roller

- Cassette & Stand Unit

- Type : Roll Exchange

- Stand Material : FC 25

- Bearing Metal Material : SS41

- Cassette Frame : 5 Stages × 9 Sets

- Stand : 25 Stages × 1 Set / 20 Stage × 1 Set

- Shaft : SCM4, Ø70mm

- Bottom & Top Roll Setting : Top Screw

- Roll Shaft Key Home : 12 × dp5

- Stand Attaching : High Tension Bolt

- Stage Distance : about 500mm

- Drive Motor Line

- Main Motor : DC Motor 37Kw

- Reducer : Worm Reducer 175 type 20 : 1

- Drive Joint : Chain Drive

- Main Motor Speed Control : DC Control

- Cassette Drive Joint : By Pneumatic Cylinder

- Forming Roller

- Roller Material : SCM 21

- Roller Stage : Depending on Products

- Roller Quantity : Depending on Products

Straightener

- Type : Block Straightening Type

- Operation : By Handle

- Quantity : 1 Set

Cutting Press & Cutting Mould

- Cutting Press

- Type : Hydraulic Flying Cutting by AC Servo Motor

- Cutting Drive : by Hydraulic Cylinder (25,000Kg)

- Frame : Channel & Welded Steel Structure

- Hydraulic Pump : 75L

- Hydraulic Motor : 7.5Kw

- Tank : 300L

- Up/Down : Manual & Screw Type

- Cutting Mould

- Type : Shear & Double Cutting Type

- Cutting Scrap : max. 8mm & 0mm

- Material of Box : SM45C

- Mould material : SKD11

Unloading/Sliding/Auto Stacking Conveyor

- Type : Roller Conveyor Type

- Conveyor Speed : 18m/min

- Drive : 2.2Kw AC Geared Motor

- Frame : Channel & Welded Steel Structure

- Sliding : by Pneumatic Cylinder

- Side Guide : Channel & Welded Steel Structure

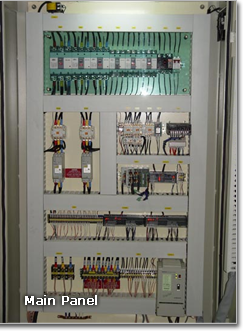

Electric Control System

- Main Control Panel

- Series of Terminal Blocks

- Well Organized Wiring System

- Operation Panel

- Type : Button or Touch Screen Type

- Location : Beside of Front Side of Roll Former

- PLC

- Newest PLC from LG

- Electric Consumption : about 90Kw